Lager Fermentation Timeline | Learn How to Correctly Ferment Lager

Do you like to brew your own beer? but are you careful about starting to brew a lager? I totally understand why. Lager is not like other beers, it takes longer to ferment, it requires different handling, and more attention.

How long does lager fermentation take? It can take up to 1-3 weeks or more for lagers to ferment, and the final gravity might not even be reached after the primary fermentation. Lagers ferment at lower temperatures than ales, and yeast metabolism works slower at these temperatures. Therefore it takes a longer time to ferment lagers.

But that’s not all, there are much more to know about lagers fermenting process. Keep reading this post as I will take you through everything you’ll need to know about lager fermentation.

Read Also: How Long Can I Leave My Beer In The Fermenter?

What Is the Lager Process?

Brewing lager at home is a bit more comprehensive process than brewing other beers. Therefore this beer is less attractive for most homebrewers. But let’s just start from the top.

This process that I am about to go through may not be the absolute best to use when fermenting lager, but if you have never brewed lager before this is the process you should use, as it’s very simplified.

When I was brewing my first batch of lager I used this process because I wanted my very first batch of lager to be a success, and it did become a success. Let’s begin:

- One day before your actual brew day, you should start the starter. Pitch a 2 liter well-aerated starter with an activator pack or vial of your chosen lager yeast.

To let it start fermenting, store this starter at room temperature 20°C – 21°C (68°F – 70°F). This lager yeast might secrete sulfur notes, but don’t worry, this is totally normal for lager yeast.

- If you are brewing an original gravity lager, this beer will not result in toxic alcohol levels for the yeast. This will make for a more forgiving fermentation.

When this is brewed you will chill the wort down to a temperature under 15°C (60°F). If this is not possible for you, try to let the wort cool down in your lagering fridge before pitching.

- While transferring the wort to the fermenter you have to leave the hot break and hop in the kettle. This can be achieved with whirlpooling.

The wort needs to be aerated well before it’s transferred into the fermenter. To obtain a healthy lager fermentation it needs more oxygen than an ale of the same strength. The reason is to reduce the stress on the yeast.

An oxygen level of 8-10 mg/L (ppm) would be best achieved through 20-30 minutes of sterile air.

- Now, pitch the starter into the primary fermenter. When you can see fermentation activity, you can move the fermenter to an area with constantly 9°C-11°C (48°F-52°F).

Now the primary ferment will take its course for around 2-4 weeks until the airlock activity stops. - When the primary fermentation has finished, rack the beer into a lagering vessel. This could, for example, be another carboy.

When this is performed, the beer shall be moved to another area where the ambient temperature is around 0°C-3°C (32°F-38°F). Here it will remain for at least another 4 weeks. - Then the 4 weeks has passed, you can rack to a serving keg and force carbonate, in case you didn’t do the force carbonation during lagering, or bottle.

If you choose to bottle condition your beer, you may want to add fresh yeast with the priming sugar. The yeast in the present will not perform as well anymore when the beer is around 6-7 weeks old. Use ¼ to ½ pack of dry yeast.

Let the beer carbonate at room temperature. The higher the temperature is, the faster the beer will carbonate.

For more information about lager beer, read this post, as it will take you through all kinds of lager beers: How Many Types Of Lager Are There?

History of Larger Brewing

Cold storage of beer in places like caves is an old practice, that was common back in the medieval period.

Before the refrigeration arrived, German brewers dug cellars where they could keep the beer for lagering. They filled up the cellars with ice from lakes nearby, to keep the beer cool during the summertime.

To protect the cellars further they planted chestnut trees which have dense vegetation of leaves, but short roots, so they wouldn’t grow into the cellar.

As the development of refrigeration grew, as did the lager. Now it was suddenly easier to store the beer cool, and it was easier to brew the beer year-round.

The first large-scale refrigerated lagering tanks were developed for Gabriel Sedelmayr Spaten Brewery in Munchin by Carl von Linde in 1870.

Does Lager Yeast Take Longer to Start?

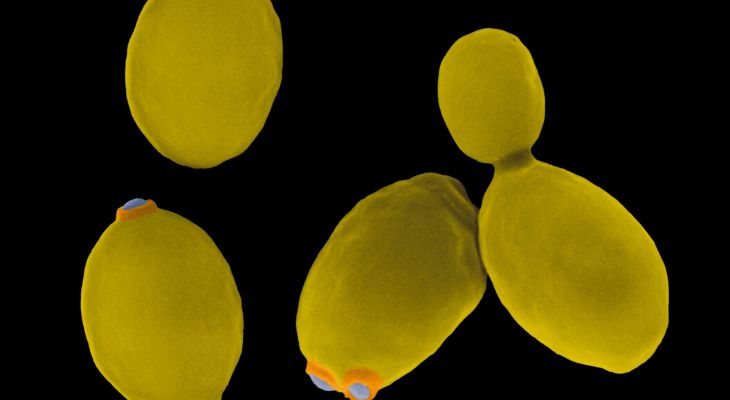

The yeast used in lager fermentation (Saccharomyces pastorianus) is a bottom-fermented lager yeast.

This kind of yeast can ferment at a lower temperature than the top-fermenting ale yeast. By letting the beer ferment and mature at a lower temperature, you reach a cleaner flavor profile.

This extended cold lagering is also resulting in longer shelf life of the lager beer. Maybe that’s why most of the world’s beers on the shelves are of the lager variety, rather than the ale variety.

Lager yeast works slowly, but they are very thorough. They consume a wider variety of sugars than ale yeasts do. This helps produce that characteristic dry finish.

As mentioned, Saccharomyces pastorianus is the yeast used in lager beer. This yeast has a complicated genome and appears to be the result of hybridization of two pure species in the Saccharomyces species complex.

Are you even more curious about yeast in beer brewing, you should try out this post: How Many Times Can You Reuse Yeast?

How Long Does Fermentation Take for a Beer?

There are various beer types, and they are brewed in different ways which also mean, that they have different timelines. In the following, I’ll take a baseline in an ale fermentation timeline to show the difference between Ale and Lager fermentation.

Ale Fermentation Timeline

- Start by chilling the wort to the target fermentation temperature. Attach insulated temp robe to the side of the fermentor, and pitch the yeast starter. This will take around 2-5 days.

- After the 2-5 days of active fermentation, remove the robe from the side of the fermenter.

- After another 2-5 days, cold crash the beer.

- Around 12-24 hours later, fine with gelatin.

- Then 24-48 more hours, package the beer.

Now, this is not a long timeline. Of course, the beer is not finished already. When the beer is racked to the secondary fermenting it has to be stored for around 2-3 more weeks before packaging.

But, the lager is a different story. I need to say, that there are many different ways to do this, therefore there are various answers, and none of them are incorrect.

The primary ferment of the lager will take its course for around 2-4 weeks until the airlock activity stops.

After, the beer shall be moved to another area where the ambient temperature is around 0°C-3°C (32°F-38°F). Here it will remain for at least another 4 weeks.

Lagers ferment at lower temperatures than ales, and yeast metabolism works slower at these temperatures. Therefore it takes a longer time to ferment lagers.

In the section above, you can read all about the lager process. But, the bottom line is that lager is a more needy beer to brew, but if you have the patience, you will succeed.

For more knowledge about brewing beer at home, read this post: What Is The Best Home Brewing Kit for Beginners?