What Is a Manometer? » Manometer one guide!

Are you a home-brewer with a big ‘H’, and are you in love with devices that are used in brewing, such as manometers? Then you have entered the right place to get all of your questions about manometers answered.

What is a manometer? A manometer is a device that can measure pressure. Manometers are often used to measure the pressure of a contained gas, but also in beer brewing.

The manometer can read if there should be an over-pressure, to secure a trouble-free operation of a brewery. A manometer is also used for a lot more than brewery.

Keep reading this post, as I will take you through everything about a manometer. Both why and how you use it for brewing, but also how and why you use a manometer in other contexts.

Read Also: Best Moonshine Still Kits

What is a manometer and how does it work?

A manometer is used for several purposes. Both while brewing beer, but also to contained gas, to measure the pressure.

Manometer in beer brewing

The purpose of a manometer is, in this case, for a mash tun application. To keep an eye on and control the differential pressure or the suction, both within and across the grain bed.

The manometer can give you a visual rendering of the speed you pull the wort through the grain bed. This is done by help from the difference in the levels between two pipes.

The more number of brew you complete, the more sense it makes to you, how to install the pump speed, and that the performance of the lautering should be based on the manometers reading.

My Recommended Manometer

- [ 11 Selectable Units&High Accurate ] This gas pressure meter features 11 selectable units of measure.The device measures gauge and...

- [ Date Hold & Max/Min/Avg Recording ] Pressthe HOLD button momentarily to freeze the displayed reading. Zero function for offset...

- [ Portable ] The digital gas manometer dimensions:5.79" x 2.16" x1.26",Slim design and easy button for one hand operation,free up a...

Last update on 2026-02-10 / Affiliate links / Images from Amazon Product Advertising API

Mash tun

But what exactly does mash tun mean?

While talking about mash tun, we are talking about the mashing process. While brewing beer, this process is usually done in a vessel called a mash tun.

This mash tun is similar to brew kettles. The difference here is, that mash tun is highly isolated, to be able to maintain the constant pressure.

For more knowledge about beer brewing at home, try out this post: What Are The Best Airlocks For Homebrewing?

How does the manometer work?

While talking about manometers, we’re talking about pressure. It’s almost impossible to not apply to pressure while talking about physic processes. Pressure has mathematically its simple form P=F(force)/A/(area).

The manometer is especially playing a role in fluid dynamics. When I say fluid, I mean that fluid consists of a substance in either a liquid or gas state.

An example here is, that the atmosphere around us is fluid that exposes us to a major constant pressure, and we don’t even notice it. But what exactly is pressure?

Pressure is a superior measure of the effect F (force) over a surface. This will typically be measured in Pascal (Pa).

How is the pressure measured?

As mentioned above, a manometer is a device that measures air pressure. This section is based on how a manometer works when measuring gas pressure.

This is done using a container with a ‘’U’’ shaped tube, that can either be open in both ends or simply just in one of the ends.

First up, a test is introduced in the one end of the closed thermometer, which is then chapped. Then a fluid is poured in the other end. It’s very important to know what density the fluid has.

The liquid will stop move when the gas that is trapped between the cap and the liquid matches the pressure (on the same side) in the bottom of the fluid column, the air pressure, and the pressure from the fluid column on the other side.

The height of the liquid will be higher on one of the sides when the air pressure is less than the gas pressure. Thereby it will be lower on the open side when the air pressure exceeds the gas pressure.

What Is a Manometer Used For?

Depending on the type of manometer we are dealing with, it can be set to provide different pressure value measurement. One of the most well-known manometer types is a sphygmomanometer that doctors use to monitor blood pressure.

This type of manometer though is far from the only kind that exists, and all types have, more or less, different functions.

In the following, I will explain to you the different kinds of manometers, what they are used for, and how to use them.

Specific pressure categories

In general, pressure is presented in three categories:

- Absolut pressure

- Gauge pressure

- Differential pressure

Absolute pressure is a method where the value of the pressure that is exerted relative to the absolute zero pressure in a vacuum is measured.

Gauge pressure is the difference between the pressures measured value and the local atmospheric pressure. Here, think in terms of a tire pressure gauge.

Differential pressure is used as a description of a performed measuring, that is the difference between two unknown pressure levels, where there isn’t a specified reference pressure. The measure of this amount of pressure, by which the two differ, is still important.

Thereby the total or absolute pressure can be defined in terms of gauge pressure and atmospheric pressure as follows.

Beer brewing

The international measurement of pressure is Pascal (Pa). By more technical applications the measurement will typically be Bar or Pounds Per Square Inch (PSI). Thus: 100 kPa = 1 bar = 14.504 psi.

Reading a manometer indicates an over-pressure relative to ambient pressure. Normally this is 1 bar. A reading of 0 bar, therefore, means 0 over-pressure, or absolute pressure of 1 bar.

While brewing beer, the quality of the pressure measurement is very important. Therefore, to ensure the most trouble-free brewing, the manometer is used in several steps during the process.

Following is measured:

- air pressures in pneumatic valve systems

- CO2 pressure in fermentation tanks

- differential pressure under lautering

- beer pressure in dispensing systems

- absolute and differential pressure at the bottling line

- steam pressure

- glycol pressure

- water pressure

Also, indirectly they can determine volumes by help from pressure transducers.

During the filling of the beer, it’s very important to apply a manometer of high quality, as this will result in avoiding potential dangerous over-pressure or inaccurate CO2 levels in the finished beer.

While being a beer brewer the most simple manometer is one with two sight glasses on the lauter tun. One of them has an inlet above the false bottom, while the other one has an inlet below.

The brewer can then get a feel over for the situation by looking at the fluid level in each tube, and sense the differential pressure across the grain bed and adjust the lautering accordingly.

Also in brewing beer, another little device can be used. This is called an aphrometer.

Aphrometer

An aphrometer is used for carbonated drinks. This applies to both amateurs and professional producers. The aphrometers’ function is to keep the pressure inside the bottle in control and, indirectly, the quantity of carbon dioxide in the beer (and other carbonated drinks).

The aprometer is, unlike all other models on the market, easy to handle, small dimensions, content cost tool. This fix little element makes it almost perfect for both professional and home brewing.

Also read: What Are The Best Bottles For Homebrewing?

What Is a Manometer Test?

A manometer is used to measure the pressure difference between two gases. Often this will be between the gas that are tested and the atmosphere. An example of a typical manometer is a U-shaped tube filled with either mercury or liquid.

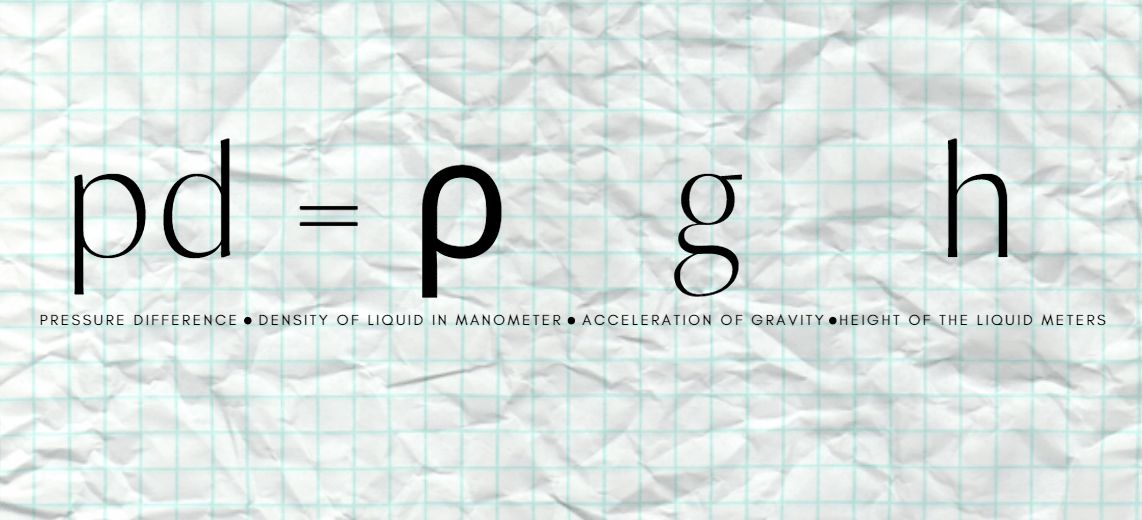

The formula for calculating the pressure: Formula pd = ? g h

| Formula pd = ? g h | Content |

| pd | pressure difference |

|

? | density of liquide in manometer |

| g | acceleration of gravety |

| h | height of the liquide meters |

I will now take you through the test. This is what you will need:

- a manometer

- gas to be tested

- a calculator

The tube is marked with millimeter dimensions on the long sides. Here a gas pipeline is connected. When the cord is plugged on one side of the manometer, the height of the liquid on both sides will change.

This height difference is used to calculate the pressure on the gas line.

Afterward, the left side of the manometer tube is put together with a pressure test valve.

All depending on which manometer that are used for the test, you can, with advantage, use the connector tubes on the manometer, or you can remove the tubes and use the tube on the item that are being tested, if available.

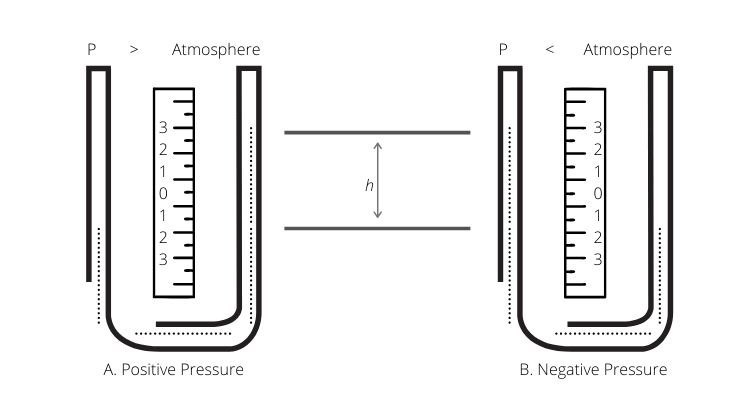

Allow the liquid to stop moving in the U-tube before measuring. Note the liquid height of the left tube. The measurement will be positive if the liquid height is lowered. Is the liquid height, on the other hand, higher than the initial height, the measurement is negative.

Now, note the liquid height in the right tube. This measurement will always be positive, no matter if the liquid height is rising or falling. The liquid height from the left tube is now subtracted from the right tube’s liquid height.

This simple calculation will give you the height shift of the liquid.

Call the height difference for h in the pressure difference formula, as mentioned in the introduction: pd = ? g h. Use the density of the liquid specific to the manometer you are using. And at the final, calculate the pressure of the gas being tested.

How Do You Read a Manometer?

In this case, we will take a look at how to read a u-shaped manometer, which measures pressure differences. So, all in all, it will proceed as the test above.

The liquid inside a u-shaped manometer is usually mercury. When both sides are open to air, the level of the liquid will be the same on both sides.

When a gas pressure is connected to one side, the pressure can be calculated (read the section above) by taking the difference in height between the two sites.

Closed-end vs. open-ended manometers

A closed-end manometer is not open to the air. To read a closed-end manometer, take the difference between the heights of the two columns of mercury.

An open-end manometer has, on the other hand, one side open to atmospheric pressure.

To read an open-end manometer, the difference in height of mercury between the two columns is due to the pressure between the gas attached to the closed-end and the air pressure.

If the columns of the mercury is higher in the open end than on the end attached to the gas, that means the gas pressure is greater than the atmospheric pressure.

- gas pressure > atmospheric pressure

- Pgas = Pair + height difference

The pressure of the gas then is equal to the air pressure and the height difference. If the column of mercury is lower in the open end connected to the gas, that means that the gas pressure is less than the atmospheric pressure.

So, the pressure of the gas is the air pressure minus the height difference.

- gas pressure < atmospheric pressure

- Pgas = Pair – height difference

What Are the Types of Manometer?

As mentioned before, there are different types of manometers. The diversity is in general defined as analog manometers and digital manometers. I will go through the two different types of manometers in the section below.

Analog manometers

The different analog manometers are:

- U-shaped tube

- Well type manometer

- Absolute manometer

The first analog manometer is the above mentioned U-shaped tube. In the sections above we have reviewed what a U-tube manometers’ applications are. Below I have made a list to sum it all up.

Applications of U-tube manometer:

- It is used for low range pressure measurements.

- Extensively used in laboratories.

- Is used in Orifice meter and Venturi meter for flow measurements.

- It is used for calibration of gauges and other instruments.

- It is used for measuring pressure drop in different joints and valves.

Another type of analog manometer is the ‘well type manometer’. This manometer is also called a cistern manometer.

This well type manometer is almost the same as the U-shaped manometer. The only difference here is, that the U has a cross-sectional area, that is larger than that of the other leg.

This makes the liquid level in the left leg less moveable when it’s exposed to the pressure.

Another type of analog manometer is called an absolute manometer. This absolute manometer only has one sealed leg, so that only one leg of the manometer tube is permitted to be exposed to the outside pressure.

The different analog manometers are using various fluids. If the fluid is changed it can change the analog manometers accuracy, range, and sensitivity.

Fluids with a higher density than water gives higher intervals, but lower resolution. But also the other way around. So similarly lowering the density of the manometric fluid, decreases the pressure range, but increases its sensitivity.

Digital manometers

Digital manometers are not dependent on hydrostatic weight balance to evaluate and decide a particular pressure. The digital manometers contain a pressure transducer.

A pressure transducer is a device that can convert an observed pressure level into an electric signal whose characteristic value is proportional to, or a proxy for, the magnitude of the pressure.

The electric part of the transducer deflects under pressure. That deflect is then converted to a value of an electrical parameter that can be detected and calibrated into a pressure reading.

How do you make a manometer?

Is it really possible to make your own manometer? The answer is yes, indeed.

So here I give you a step-by-step guide in how do make a manometer.

The only things you will need is:

- 100 ml of water

- 500 ml beaker

- 5 ml of food dye

- 4 feet plastic tubing

- 2 foot long (thin) wooden plank

- Hammer

- Tube fasteners

- Ink pen

- Nails

- Ruler

- Plumb line

- Tape

Are you ready? let’s begin!

- First up, you have to put the plastic tubing around the length of the plank. For this, you will have to use the tube fasteners. It’s important to make sure that the tubing makes a smooth ‘U’ formed bend around the end of the plank.

- Now place it toward a vertical surface. Optionally a board. To make sure the plank is totally vertical you can use a plumb bob. Fasten the plank on the board by using a nail or similar, that can fasten this.

- Pour around 100 ml of water into the beaker, and add the fruit color. Rather a little too much, than a little too less. Afterward, pour the colored water into the tube.

- Place a measuring device on the manometer, on the opposite side of where you expect the pressure. Line up a zero point of the measuring device at the surface of the liquid. Attach it with tape, or similar.

- Last, but not least, fasten a source of positive pressure to the end of the manometer. Make sure it’s with an airtight seal.

And there you have it! The pressure can now be measured by inches of colored water.

What Is Manometer Fluid?

Most manometers contain some fluid. And there certainly are several different kinds of manometer fluids. The most common manometer fluid is the red oil manometer fluid.

Red oil manometer fluid

Red manometer fluid contains a small percentage of dye. Base fluid consists of paraffin, light naphthalene, mineral oil, kerosene, CFE or ethylene glycol. This all depends on the specific applications of chemical compatibility and temperature environment.

When a colored indication fluid like this is used instead of water, the manometer is being adjusted to reflect the indicating fluids specific gravity.

What Is Single Column Manometer?

A single column manometer is a modified form of a U-tube manometer in which one side is a large reservoir and the other side is a small tube, open to the atmosphere.

There are two types of single column manometers:

- Vertical single column manometer.

- Inclined single column manometer.

Vertical and inclined single column manometer

A single column manometer is a modified form of a U-tube manometer. There will be a reservoir with a big cross-sectional area around 100 times compared to the area with the glass tube.

A limb (let’s make it the left) of the glass tube will be connected with the reservoir, and the other limb (to the right) of the glass tube will be open to the atmosphere.

This complete setup is called a manometer with a single column (a single column manometer). The pressure is measured on a point in the liquid by connecting the one columns manometer with the container of liquid, whose pressure is to measure.

The rise of the liquid in the right part of the glass tube gives the pressure head.

There are basically two types of manometers with a single column based on the manometers right point:

- Inclined single column manometer

- Vertical single column manometer

What is an inclined manometer?

An inclined manometer is a slightly curved tube with liquid inside. This liquid would usually be a form of an oil mixture, that typically is used for manometers.

Along the tube’s middle portion are graduations.

Usually, the graduation is a hundredths of an inch. When the manometer is put into service, a pressure is formed.

The pressure that arises from the flow puts pressure on the internal liquid. The amount of liquid displacement is viewed and measured through the tube’s graduation, producing a pressure value.

Inclined angle

The manometers inclined angle gives it many advantages. This type of manometers is very sensitive and very accurate. Even a small or very low pressure towards the inclined manometer will cause big liquid movement, compared to the size of the tube’s graduation.

This graduation scale can be precise down to a hundredth of an inch accurately, as mentioned above. Other than that, the inclined manometers’ simple design makes it more inexpensive.

What Is a Differential Manometer?

In general, a differential manometer is a device that measures a difference in the pressure between two places. These manometers can variate from the most simple devices to more complex devices, that have to be installed at home to complex digital equipment.

A differential manometer is also used to compare the pressure of two different containers. The opposite is the standard manometer, which is used to measure the pressure in a container, by comparing the normal pressure with the atmospheric pressure.

But, they have that in common, that they both reveal which container has greater pressure and how large the difference between the two is.

Functions

A differential manometer has a row of different uses in different disciplines. An example is, that they also are used to measure the flow dynamics of a gas. This is done by comparing the pressure at different points in the pipe.

Read Also: Is A Refractometer More Accurate Than A Hydrometer?